[Original] Why is it necessary to conduct the grounding resistance test?

[Original] Why is it necessary to conduct the grounding resistance test?

It is also known as grounding continuity test. The test should be conducted on all class I products. The purpose for the test is to ensure all conducting components of the product which can be touched by users and will turn to charged body when the single insulation is failure are connected to the ground point of the power input. In other words, a grounding test is to verify the integrity of the grounding path by connecting a high current low-voltage power supply to the ground loop.

To judge if the product complies with the standard and requirement, the protective impedance between the grounding connection terminals or grounding contact and the components should be measured. It is considered complying with the requirement if the impedance does not exceed a fixed value which is determined by the product safety standards. Be sure to remember, from the structure and design point of view, the conductor which is used for protecting grounding should not contain any switches or fuses.

Test requirements:

Most of the standards have parameter requests for grounding test.

· The EUT must be under the high DC or AC but low voltage for a certain period of time.

· The potential fall between the grounding connection terminals or grounding contact and the components must be measured

· The resistance value must be calculated by current value flowing through it and the potential fall generated.

The impedance should be no more than a certain value which is different in different safety standards. For example, the test voltage is required no more than 12V in IEC 60950-1. The current can be AC or DC, and the current value should be 1.5 times the rated current of the product or25A(choose the bigger one). The test duration must be exactly 1 minute and the protective impedance between the grounding connection terminals or grounding contact and the components that should be earthed must be no more than 0.1? (not including the impedance of the cables). In some standards, such as CAN/CSA-C22.2 No. 60950-1 or UL 60950-1 (including the difference of Canada), if the rated current of the product is no more than16A, the test current should be40Aand the test duration should be 2 minutes.

In most standards except the Canadian standard, the test current is required less than25Aand the duration is 1 minute which means the biggest current and longest operating time can be stood by the overcurrent protective device. The maximum current value,25A, is 1.5 times the rated value of most wires connect to the setup switches of the inserted type A devices, which is no more than16A. The requirements of Canadian National Wiring Code are very similar to the above requirements. They assume that the lifetime of the fuses is no more than 1 minute when it is under 2 times the rated current value. It is said in the UL standard that the fault current will be40Aand the duration is no more than 2 minutes because of the use of20Aline switching protection in most power circuits.

[Original] Why is it necessary to conduct the voltage proof test? (Part I)

Dielectric strength test, also known as hipot, is probably the most well-known production line safe test and is performed frequently, which suggest that it is an important part in every standard actually. Hipot is a nondestructive testing, whose purpose is to confirm that electronic insulation materials can resist instant High voltage. It is a high voltage test which is used for all devices to make sure that the insulating material is sufficient. Another reason of hipot is that it can find out the probable flaw such as the insufficient of leakage distance and clearance caused in manufacturing process.

In type tests, hipot is done after other tests (such as failure test, dampness test or vibration test) to examine whether there is insulation deterioration caused by those tests. However, the hipot in current production is a kind of test in manufacturing process to make sure that the structure of the product is the same as the one used in the type tests. Some flaw caused in manufacturing process can be found out in the on-line hipot, such as the diminishment of the clearance and the creepage distance of transformer winding. Such kind of failure may caused by a new operator in winding department. Other examples include examining the pinhole flaw of insulation materials or finding an oversize soldering point.

Most safety standards use the convention of 2xU + 1000 V as the basis of insulation material test. The U here means operating voltage (value rms). The convention is just a guide to provide a detailed form to individual standards especially IEC 60950. This form is used for defining how to confirm a certain test voltage according to the voltage measured in actual operation. The reason of using 1000V as fundamental convention is because it is the affordable transient over-voltage of the insulation material in daily use. Experiment and research show that the voltage at these circumstances is usually ran up to 1000V.

Test Method:

High voltage is usually used in the two components over the insulation material under test, such as the primary circuit and the metal shell of the EUT. If the insulation material between the two components is enough, the high voltage between the two components separated by the insulation material can generate very little current flowing through the insulation material. Though the small current is acceptable, breakdown should not occur to the air insulation or solid insulation. Therefore, it should be noted that this current is caused by partial discharge or breakdown, but not caused by capacity connection.

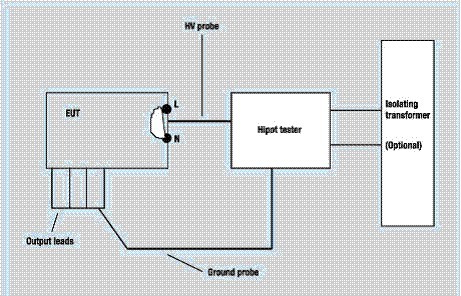

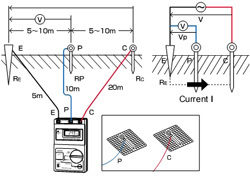

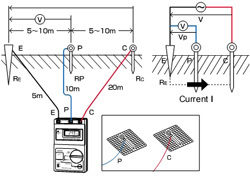

Another example is the test of the insulation material of the power supply between the primary and secondary circuit. At this time, all outputs short together. The ground probe of the hipot tester connects with the outputs and the HV probe connects with L and N (L and N are shortened). (See also picture 1) the EUT should not work when it is under a hipot. There is one thing should be noted. In the period of the type tests, the ideal condition is that the voltage should be less than 1/2 rated voltage at the beginning, following by gradually increase till it reach the rated voltage in 10 seconds, and that should last for 1 minutes. However, for most test instruments, the rated voltage is output directly or reached step by step by using an electronic control circuitry.

The picture is as follows:

Picture1. Connection diagram of type tests

Test duration:

If the test is one part of the certification process, the test duration must in accordance with the safety standards. For example, in most standards, including IEC 60950, the test duration is 1 minute. However, when the test is under test in the production line, it is unpractical to conduct a hipot on every product for 1 minute. The producer will always shorten the test duration, like several seconds, but use higher voltage instead. A typical empirical rule for this is 110-120% (2xU+1000 V), 1-2 seconds. The test duration and procedures should be approved by the related testing agency. It is worth be noted that every insulation material has its own specific voltage duration according to tests and the data of producer, though the time shortened is about the same as the voltage increased.

[Original] Why is it necessary to conduct the insulation resistance Test?

The insulation resistance test is also known as Megger test. The purpose is to measure the total resistance between the two spots that are separated by insulation materials. Therefore, the test can confirm how much effectiveness is made when the insulation resistance resists the flowing current. The current is very low, because the voltage in the test is usually 500~1000Vdc. Because of the low current, the test is useful to examine the quality of the insulation materials, not only when the products are being produced, but also when they are in use.

Test procedures: EUT

To connect it to the tester and make the test voltage increase from 0 to the maximum value (usually 500 V dc). At the moment the voltage reaches the maximum value, keep that value for a while (usually 5 seconds), and then record the resistance value. The measured value should be very high (usually in the teraohm level). The measure of insulation resistance is a mandatory requirement in some standards, such as IEC60950-1 and UL6500.

[Original] Why is it necessary to conduct the Voltage Proof Test? (Part II)

Current setting:

Nowadays, most hipot testers allow the users to set the limit value of the current. However, if the actual leakage current is known, the test current of hipot is predictable. The selection of the limit value is in accordance with the products under test. The best way to select limit value is to work out an average current by making hipots on some product samples. The limit value of the leakage current is set to a higher value than the average one. The other method to set limit current value is to use the following mathematical formula:

The picture is as follows:

The reason why using 2 as the factor is that the leakage current of the circuit is produced by a capacity Y, but the leakage current of the hipot is produced by the capacities of every circuits together. You can predict the hipot current by deriving the equation of I (hipot). Therefore, the limit current of the hipot tester should be set high enough to avoid the misjudgment caused by the existence of the leakage current, but not too high to examine the breakdown of real insulation materials.

Most standards allow using AC or DC to make a hipot. When AC voltage is used in the test, the voltage stood by the insulation materials under test is the peak value. Therefore, if you decide to use DC for test, you must make sure that the DC test voltage is Ö2 times (or 1.414 times) the AC test voltage. In this way, the peak values of both the DC and AC voltage are the same. For example, if the voltage value is 1500 V AC, the equivalent DC voltage value for insulation test should be 1500 x 1.414 or2121 V DC.

An advantage of using DC voltage for test is that the limit leakage current can be set to a lower value than using AC voltage instead. In this way, there are greater chances for the producer to find out the products whose insulation materials are losing effectiveness. These products may probably pass the AC voltage test. It must be noted that the capacitors in the circuit are highly charged when AC hipot tester is used. Therefore, it is necessary to use a safety discharge equipment and set it correctly. However, no matter which kind of voltage is used, it is a good way to discharge the product before it can be touched by people.

Another advantage of the DC hipot tester is that its voltage increases gradually. The operator can find out the potential failure of the insulation materials before by monitoring the current changes when the voltage increases. A little weakness of the DC hipot tester is that its cost is a little higher than an AC hipot tester, for the former more difficult to produce.

There is a little abuse of the AC hipot tester. If there are large-capacity capacitors Y in the circuit under test, the AC tester may tell a failure because of the setting of the limit current of the hipot tester, but the insulation materials have no breakdown. Most standards allow users to test with the capacitor Y cut off or to use the DC hipot tester. The DC hipot tester will not tell a failure because of the existence of the large-capacity capacitors Y, because the current will not flow through the capacitor Y under DC voltage.

[Original] Why is it necessary to conduct the Leakage Current Test?

In some standards, including IEC60950-1, leakage current is named as touch current. In other words, it is the current flowing through human bodies or animal bodies when a person or an animal touches a touchable part of a device. There is another conception called protective conductor current, which is equal to the current flowing through the protective conductor. Therefore, protective conductor current has never been the reason causing electric shock because protective conductor is always connected to the ground according to the definition.

If the contact current is too high, the operator will be shocked, and that may lead to serious damages which are related to the operator’s weight. Usually, if the current is more than 1.0mA and flows through human body, it can cause electric shock damage. The extent of damage is related to the current value and the person’s weight.

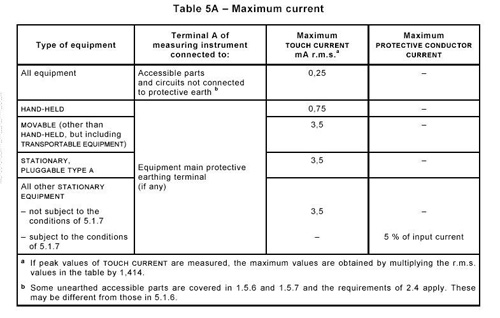

Similar to other tests, leakage current test is another important part of the safety tests. In most safety tests, the test should be under different conditions, such as normal operating condition, switch on and off, and exchange of the power cord polarity. The earth leakage current should be no more than the limitation under any conditions. Table I lists part of the usual limit.?IEC60950-1, Table 5A?

The picture is as follows:

The biggest contributor of leakage current is the capacity over the live wire and the ground, such as capacity Y. The capacity Y is usually added into the circuit in order to control EMI. It must be noted that in some standards, such as IEC60950-1, the earth leakage current of class I vertical devices is allowed to exceed 3.5mA if it meets the conditions in section5.1.7of IEC60950-1 at the same time.

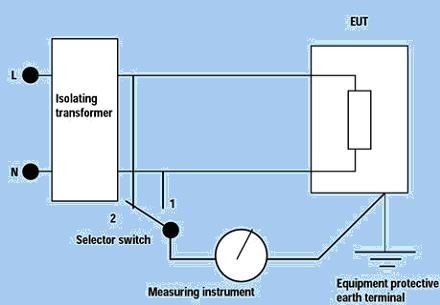

In the leakage current test of the IT equipments, it must be noted that the tester should be in accordance of the requirements in appendix D of IEC60950-1. This test makes a network simulation of the worst situation of body resistance. It is strongly recommended to use an isolating transformer for the test.

The picture is as follows:

Any capacitive leakage current of the transformer must be considered. If it is for some reason impossible to use an isolating transformer, the EUT must be fixed on an insulating desk and appropriated safety warning should be posted. This kind of measurement is a make-up for the possibility of the dangerous voltage carried by the EUT.

Test Method:

Most standards, especially IEC0950, require the EUT to be in the state of power-on. The supply voltage of the EUT is 110% of the upper limit of the rated value and the frequency is the maximum rated frequency. As previously mentioned, for the sake of safety, it is strongly recommended to use an isolating transformer for the test.

These tests can be done for both class I and class II. For class II, the touchable conductive components and metal shell should be tested. You can touch the shell surface with metallic film (10*20cm) which imitating human hands.

This test can be also done under any conditions, such as normal operating condition, switch on and off, and exchange of the power cord polarity. The devices which include multi power input must be tested with only one power on if they are required to be used with one power on each time (such as back source). Though most standards do not require a 100% leakage current test on the production line, some special standards, such as those for medical instruments, ask for a 100% test.