1. General Overview of AQL Inspection

1. General Overview of AQL Inspection

AQL, the abbreviation of the acceptable quality level, is a parameter rather than an inspection standard. The Inspection of goods shall be in accordance with the bulk range, the inspection level, and the AQL to determine the number of samplings and the ratio of qualified and inferior goods. The quality inspection adopts a one-time sampling program, and,

The AQL is 2.5,

The Level of Inspection: Normal

Stringency for the Inspection: Normal

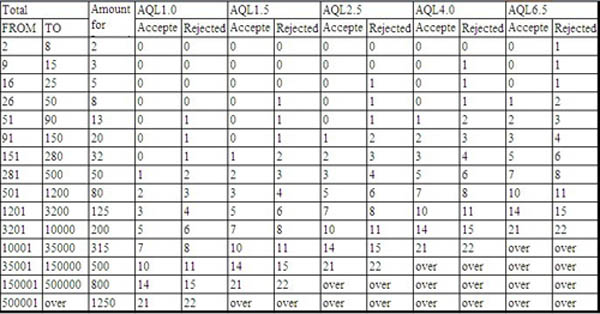

And the sampling plan is shown in the Table below:

One-time sampling program for normal inspection: (AQL-2.5 and AQL-4.0)

2. Clothing Inspection Items

1). Inspection of the Size and Shape—Table of Size and Shape

(1) Key sizes and spots— collar length (plain weave), collar width (knitting), collar spread (knitting) circumference, sleeve openings (long sleeve), sleeve length (to the sleeve edge), back length (plain weave), center measurement(knitting)/measurement of the shoulder top, pants, waist, and hip measurements, Front rise, Back rise, Zipper closure, leg opening, The inner center back length(ingle pieces / set), vertical samples, and the size of the clothing and pants.

(2).Non-critical sizes and spots — for example, the high point of shoulder, chest circumference, collar width, sleeve sheet, front rise and back rise, waist circumference , low hip , pocket position, openings.

2). Defect Checking: identify and classify the appearance, shape, dressing, and defects found in all the clothing.

See Also Annex 1 — Content of the Defects

3. Grading Standard

AQL is the total amount of the defected clothes within 100 pieces of clothes. After the sampling, if the AQL reaches the acceptance number Ac (piece), the average level of processing this batch would be regarded as satisfactory. And if the rejection number Re(piece) is reached, the average processing level would instead be rendered unsatisfactory. And the grading would be determined according to the standard as follows:

1). Normal Defects— Judging from the order specifications and quality standards, when products failed to meet the performance standard and the appearance as well as quality was affected. The normal defects at the non-critical spots can be fixed through repairing. And the garment factory repairing the defects would do a 100% recheck. And the checker can make specifications to color, size, and so on. And three normal defects can be seen as a critical one.

2). Critical defects are those that affect the shape and appearance of the clothing, which drive the consumers away from purchasing; or render the cloth uncomfortable for wearing, in which case the consumer would return the clothes. Critical defects are those damages, stains, colored strips and tears at the key spots. And even one critical defect would cause the whole batch of clothes to be determined as unqualified or unacceptable.