Test the power, the rotating speed (RPM), voltage of motor, current of motor and air volume (L/S) at different gears. Check if the heating wires become red.

2. Insulation Withstand Voltage Test

Cover the sample’s surface with metal leaf. Input the voltage of 3,750V between the metal leaf and the plug of the power cord for 1 minute. The leakage current should be no more than 0.5MA.

Demand:

there should be no electric leakage.

3. Abnormal Operation Test No.1

Test method:

- Separate the two stages of the motor and the circuit of the product. Connect the other motor to the circuit.

- Connect the motor to a separate power supply. The voltage should be 0.94 time the rated voltage when the motor works.

- Connect the motor to the working power supply. Adjust the voltage to make the power 0.85 time of the rated power.

- Put the sample in the test corner. After working for 30 minutes, measure the temperature of each spot.

Demand:

The sample should not burn or smoke. The cover should not melt.

Test result:

Measure the internal lead, air outlet, diode, capacity, the soldering point of the power cord, the surface of the power cord, the shell of the switch, the point on the surface of the front shell which is 1/2’’ far away from the air outlet and the temperature of the three points in the corner.

4. Abnormal Operation Test No.2

Test method:

- Separate the two stages of the motor and the circuit of the product. Connect the other motor to the circuit.

- Connect the motor to a separate power supply. The voltage should be 0.94 time the rated voltage when the motor works.

- Connect the motor to the working power supply. Adjust the voltage to make the power 1.24 time of the rated power.

- Put the sample in the test corner. After working for 30 minutes, measure the temperature of each spot.

Demand:

The sample should not burn or smoke. The cover should not melt.

Test result:

Measure the internal lead, air outlet, diode, capacity, the soldering point of the power cord, the surface of the power cord, the shell of the switch, the point on the surface of the front shell which is 1/2’’ far away from the air outlet and the temperature of the three points in the corner.

5. Abnormal Operation Test No.3

Test method:

- Separate the two stages of the motor and the circuit of the product. Connect the other motor to the circuit.

- Connect the motor to a separate power supply. The voltage should be 0.94 time the rated voltage when the motor works.

- Put the sample in the test corner. After working for 30 minutes, do the insulation test. (3750V,1MIN,0.5MA)

Demand:

The sample should not burn or smoke. The cover should not melt. The HI-POT should be successful.

6. 7cm Wind Blocking Test

Test method:

- Connect the sample to the supply. Adjust the voltage to make it 1.24 time of the rated voltage. The distance between the air outlet of the sample and the wall is 7cm.

- Make the sample work for 15 minutes then turn off it. After one minute, observe the tripping switch.

Demand:

The tripping switch should not break off in the whole process of the test.

7. Components Temperature Test

Test method:

Connect the sample to the supply. Adjust the voltage to make the power 1.24 time of the rated power. After working for 30 minutes, measure the temperature of each spot.

Test result:

Measure the internal lead, air outlet, diode, capacity, the soldering point of the power cord, the surface of the power cord, the shell of the switch, the point on the surface of the front shell which is 1/2’’ far away from the air outlet and the temperature of the three points in the corner.

8. Motor Deceleration Test

Test method:

- Separate the motor and the circuit of the product. Connect the other motor to the circuit.

- Connect the motor to a separate power supply. The voltage should be the voltage when the motor works at rated power

- Connect the motor to the working power supply. Adjust the voltage to make the power 1.15 time of the rated power.

- After working for 10 minutes, the voltage should be reduced at the rate of 1V per minute till the switch tripped.

- Increase the motor’s voltage at the rate of 1V per minute till the tripping stops. After working for 30 minutes, measure the temperature of each spot.

- After the sample cools down, do the insulation test. (3750V, 1MIN, 0.5MA)

Test demand:

In the whole test process, the sample should not burn or smoke and the cover should not melt.

Test result:

Test the power, the voltage when the motor starts, the voltage of the motor when the switch trips, the voltage when the motor stops, the insulation, the withstand voltage, the condition of the sample.

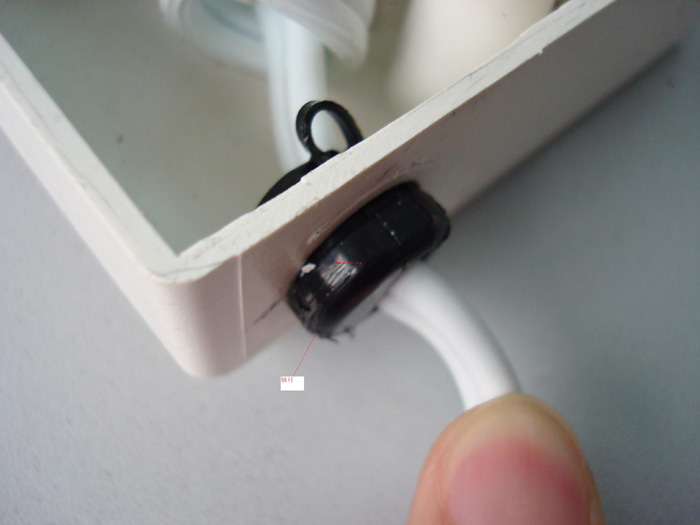

9. Power Cord Tensile Test

Test method:

- Hang heavy objects of 6.7 pound on the power cord of the sample.

- Lift the sample with the heavy objects in the most devastating direction and put the heavy objects on the ground. The whole process takes 1 second.

- Repeat the test for 25 cycles.

- Measure the length of the cord which is pulled out and observe the assembling of the power cord.

Demand:

Towed length of power cord should be no more than 2mm.

10. Air Inlet Coverage Test

Test method:

Connect the sample to the rated voltage. Plug the air inlet with poly-bag till the tripping switch is off.

Test requirement:

During the test, the product should not melt, burn or smoke. The functions of sample are normal.

11. Air Outlet Coverage Test

Test method:

Connect the sample to the rated voltage. Plug the air outlet with poly-bag till the tripping switch is off.

Test demand:

During the test, the product should not melt, burn or smoke. The functions of sample are normal.

12. Overload Test

Test method:

- Switch on the sample and adjust the voltage to make the power meat the following requirements: If the rated power is less than or equal to 100W, it is 1.33 times the rated power. If the rated power is more than 100W but less than or equal to 200W, it is 12W more than 1.21 times the rated power. If the rated power is more than 200W, it is 1.27time of the rated power.

- The whole process of the test is 15 cycles. For the hairpin type products, working for 60 minutes and shutdown for 30 minutes is called a cycle. For the wind-cone products, working for 30 minutes and shutdown for 30 minutes is called a cycle.

- After the above test, do the insulation withstand voltage test. (3750V, 1MIN, 0.5MA)

Test requirement:

During the test, the product should not melt, burn or smoke. HI-POT test should not fail.

13. Life Test

Test method:

1. Make the sample work at 1.1 times the rated voltage for 48 hours continuously.

2. Make the sample work at 0.9 times the rated voltage for 48 hours continuously.

Test requirement:

During the test, the product should not melt, burn or smoke. The functions of the sample are normal after the test.

Engineering Design Validation Report of Engineering Department

1. Input Power Test:

Test the power, the rotational speed, wind velocity, motor voltage, and motor electric current; observe whether the heat wear turns red

2. Insulation Test:

Turn on the switch at the highest level. Cover the sample’s surface with metal leaf. Input high voltage between the metal leaf and the plug of the power cord for 1 minute. The value of the voltage is as following: single insulation, 1000V; Double insulation, 3750V.

Demand:

The leakage current is no more than 0.5mA.

3. Air Inlet Coverage Test:

Test method:

Connect the sample to the rated voltage. Plug the air inlet with poly-bag till the tripping switch is off. Record the time when the switch trips.

Test requirement:

During the test, the product should not melt, burn or smoke. If there is a fuse, it should not be broken. The functions of the sample are normal after the test.

4. Air Outlet Coverage Test:

Test method:

Connect the sample to the rated voltage. Plug the air outlet with poly-bag till the tripping switch is off. Record the time when the switch trips.

Test requirement:

During the test, the product should not melt, burn or smoke. If there is a fuse, it should not be broken. The functions of the sample are normal after the test.

5. One Machine Drop Test:

Test method:

- Turn on the switch of the sample at the biggest level to make it work at the rated voltage. (If the sample is hair pliers’ type, make it work for 2 hours, then do the following test.)

- Make the sample fall on the hard board from three different directions at the height of 3 inches.

- Examine the sample to make sure it is in accordance of the test requirements.

- The height which the sample falls off is 6 inches; repeat the procedures 2 and 3.

Test requirement:

- After the test, the functions of the sample are normal. There is no damage or crack of the components.

- In the whole testing process, insulation should not break or burn and the electrified body should not be touched by the test finger.

6. Power Cord Tensile Test: